Best Way To Ship Frozen Meat

Shipping frozen meat requires careful planning and attention to detail to ensure the product reaches its destination safely and in optimal condition. With the increasing demand for online meat purchases and the rise of e-commerce platforms, it's crucial to have an efficient and reliable shipping process in place. In this comprehensive guide, we will explore the best practices and techniques for shipping frozen meat, covering everything from packaging and insulation to temperature control and transit time considerations.

Choosing the Right Packaging

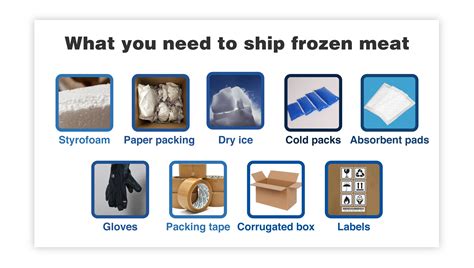

The first step in successfully shipping frozen meat is selecting the appropriate packaging materials. It is essential to use packaging that provides sufficient insulation to maintain the cold chain and protect the meat from temperature fluctuations during transit. Here are some key considerations when choosing packaging:

- Insulated Boxes: Opt for high-quality, insulated shipping boxes specifically designed for perishable goods. These boxes often feature thick insulation materials such as expanded polystyrene (EPS) or polyurethane, which provide excellent thermal protection.

- Vacuum-Sealed Packaging: Vacuum sealing is an effective method to remove air and prevent moisture buildup, ensuring the meat remains frozen during transit. This technique also helps to maintain the freshness and quality of the product.

- Refrigerant Packs: Including refrigerant packs or gel packs is crucial to provide additional cooling power. These packs can be frozen before use and help maintain a consistent temperature inside the shipping container.

- Absorbent Pads: Utilizing absorbent pads or liners inside the packaging can help prevent any potential leakage and ensure a dry environment for the meat.

When selecting packaging, it's important to consider the size and weight of the meat, as well as the expected transit time and environmental conditions. Conducting thorough testing and choosing packaging materials that have been proven effective in maintaining low temperatures is essential.

Packaging Design and Assembly

Proper packaging design and assembly are critical to the success of shipping frozen meat. Here are some key aspects to consider:

- Layering: Create multiple layers of insulation by using various materials such as bubble wrap, foam sheets, or reflective insulation. This approach provides additional protection and helps maintain temperature stability.

- Sealing: Ensure all packaging is securely sealed to prevent any air leaks. Use high-quality sealing tape or adhesives to create an airtight environment.

- Packaging Orientation: Place the meat in the center of the packaging, surrounded by insulation materials. This helps distribute the cold evenly and minimizes the risk of temperature variations.

- Labeling: Clearly label the package as "Perishable" and include handling instructions. This alerts carriers and recipients to the special care required for the shipment.

| Packaging Material | Insulation Efficiency |

|---|---|

| Expanded Polystyrene (EPS) | High insulation value, suitable for longer transit times |

| Polyurethane | Excellent thermal resistance, provides consistent temperature control |

| Vacuum-Sealed Bags | Reduces heat transfer, ideal for maintaining freshness |

| Refrigerant Packs | Provides cooling power, helps maintain low temperatures |

Temperature Control and Monitoring

Maintaining a consistent and controlled temperature throughout the shipping process is crucial to ensure the safety and quality of frozen meat. Here are some strategies to achieve effective temperature control:

- Pre-Cooling: Before packaging, ensure the meat is thoroughly frozen and cooled to the desired temperature. This helps maintain a stable temperature during transit.

- Cold Storage Facilities: Utilize cold storage facilities or warehouses to store the packaged meat prior to shipping. These facilities provide a controlled environment and can help extend the shelf life of the product.

- Temperature Loggers: Consider using temperature loggers or data loggers to monitor and record the temperature inside the packaging during transit. This provides valuable data for quality control and ensures compliance with food safety regulations.

- Transit Time Considerations: Plan the shipping route and estimate the expected transit time. Choose shipping methods that align with the required delivery timeframe to minimize the risk of temperature fluctuations.

Advanced Temperature Control Technologies

For specialized or high-value frozen meat shipments, advanced temperature control technologies can be employed:

- Phase Change Materials (PCMs): PCMs are materials that can absorb or release heat as they change phase, such as from solid to liquid. These materials can be incorporated into packaging to provide extended temperature control during transit.

- Active Cooling Systems: Some shipping containers are equipped with active cooling systems, which use mechanical refrigeration to maintain a consistent temperature. These systems are ideal for long-haul shipments or when precise temperature control is required.

It's important to consult with packaging and logistics experts to determine the most suitable temperature control solutions for your specific shipping needs.

Carrier Selection and Transit Time

Choosing the right carrier and optimizing transit time are crucial factors in successfully shipping frozen meat. Here’s what you need to consider:

- Carrier Selection: Select carriers that have experience in shipping perishable goods and can provide reliable and timely delivery. Look for carriers with specialized handling procedures for frozen products.

- Transit Time Optimization: Minimize transit time by selecting the most direct shipping routes and utilizing express or priority shipping options. The shorter the transit time, the less likely temperature fluctuations will occur.

- Real-Time Tracking: Opt for carriers that offer real-time tracking and temperature monitoring capabilities. This allows for better visibility and enables proactive measures to be taken if any issues arise during transit.

When shipping frozen meat, it's essential to establish clear communication with the carrier and provide detailed instructions on handling and temperature control requirements. This ensures that the carrier is well-prepared and equipped to handle the shipment effectively.

Handling and Delivery Considerations

To ensure a seamless delivery process, consider the following handling and delivery best practices:

- Clear Recipient Instructions: Provide clear and detailed instructions to the recipient on how to handle and store the frozen meat upon delivery. Include any specific handling requirements or recommendations.

- Delivery Timeframes: Coordinate with the recipient to ensure someone is available to receive the shipment during the agreed-upon delivery window. This minimizes the risk of the package being left unattended for extended periods.

- Return or Rejection Procedures: Establish clear procedures for handling returned or rejected shipments. Have a process in place to manage and dispose of any spoiled or compromised meat safely.

By implementing these handling and delivery considerations, you can enhance the overall customer experience and minimize the risk of product spoilage.

Regulatory and Compliance Considerations

When shipping frozen meat, it’s crucial to comply with relevant food safety regulations and industry standards. Here are some key considerations:

- Food Safety Regulations: Familiarize yourself with the food safety regulations and guidelines in your region. Ensure that your packaging, handling, and transportation practices align with these regulations to maintain product safety.

- HACCP Compliance: Implement a Hazard Analysis and Critical Control Points (HACCP) plan to identify and control potential hazards throughout the shipping process. This systematic approach helps minimize the risk of foodborne illnesses.

- Labeling and Documentation: Ensure that all packaging is properly labeled with relevant information, including the product name, ingredients, and handling instructions. Maintain accurate documentation of the shipping process, including temperature records and delivery details.

Stay updated with the latest regulations and industry best practices to ensure compliance and maintain the integrity of your frozen meat shipments.

Conclusion: The Future of Frozen Meat Shipping

As the demand for online meat purchases continues to grow, the need for efficient and reliable shipping methods becomes increasingly crucial. By implementing the best practices outlined in this guide, businesses can ensure the safe and timely delivery of frozen meat products to customers. With advancements in packaging technologies, temperature control solutions, and logistics capabilities, the future of frozen meat shipping looks promising.

By staying proactive, investing in innovative solutions, and prioritizing food safety, businesses can offer a seamless and satisfying experience to their customers, ensuring that frozen meat arrives at its destination in perfect condition.

What is the optimal temperature for shipping frozen meat?

+The optimal temperature for shipping frozen meat is typically below -18°C (0°F). This temperature ensures the meat remains frozen and prevents the growth of bacteria. It’s important to maintain this temperature throughout the entire shipping process to guarantee food safety.

How can I monitor the temperature during transit?

+To monitor the temperature during transit, you can utilize temperature loggers or data loggers. These devices record temperature readings at regular intervals, providing valuable data on the temperature conditions throughout the shipping journey. This information helps ensure the meat remains within the desired temperature range.

What are some common challenges in shipping frozen meat, and how can they be overcome?

+Common challenges in shipping frozen meat include temperature fluctuations, extended transit times, and potential handling issues. To overcome these challenges, it’s crucial to use high-quality packaging with sufficient insulation, choose reliable carriers with express shipping options, and provide clear instructions to both carriers and recipients. Additionally, implementing real-time tracking and temperature monitoring can help identify and address any issues promptly.