Constraint Resource

In the realm of resource management and optimization, the concept of constraints plays a pivotal role. A constraint resource, often referred to as a bottleneck, is a critical element in any system or process that limits the overall output or efficiency. This phenomenon is not limited to manufacturing or production lines but is a universal challenge that businesses, organizations, and even individuals encounter. Understanding and effectively managing constraint resources is paramount to enhancing productivity, streamlining operations, and achieving desired outcomes.

Identifying Constraint Resources: The First Step

The identification of constraint resources is the initial and arguably the most critical phase in resource management. It involves a thorough analysis of the entire system or process to pinpoint the elements that are causing the greatest hindrance or limitation. These constraints can manifest in various forms, from a lack of skilled labor or specific materials to inadequate machinery or even logistical challenges.

For instance, consider a manufacturing plant that produces electronic devices. If a particular component, say a specialized microchip, is in short supply or if the production line for this component is inefficient, it becomes a constraint resource. In this scenario, even if all other resources are abundant and well-managed, the overall production capacity is limited by the availability of this microchip.

Similarly, in the service industry, a constraint resource might be a highly skilled technician or a specialized piece of software. The absence or inefficiency of such resources can significantly impact the overall service delivery and client satisfaction.

Tools and Techniques for Identification

Various tools and methodologies are employed to identify constraint resources. One popular approach is the Theory of Constraints (TOC), developed by Eliyahu M. Goldratt. TOC involves a systematic process of identifying, improving, and re-evaluating the constraint to ensure continuous improvement. It includes steps like identifying the constraint, exploiting it to maximize its contribution, subordinating other processes to the constraint, elevating the constraint through various means, and finally, repeating the process if a new constraint arises.

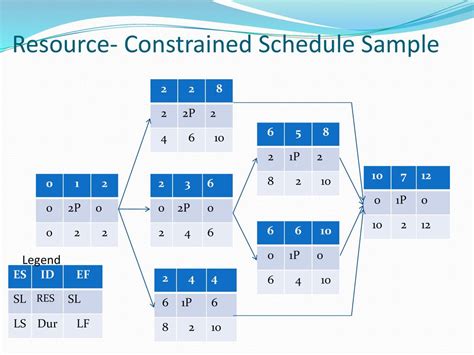

Another method is the Critical Path Method (CPM), which is commonly used in project management. CPM helps identify the longest sequence of activities that must be completed on time for the entire project to be completed on schedule. This method can highlight resources that are critical to the project's timeline and thus are constraint resources.

| Identification Method | Description |

|---|---|

| Theory of Constraints (TOC) | A management philosophy that focuses on identifying and improving the most limiting factor (constraint) in a system. |

| Critical Path Method (CPM) | A project management technique that identifies the longest sequence of dependent activities to complete a project. |

Strategies to Manage Constraint Resources

Once identified, managing constraint resources effectively is crucial. This involves a range of strategies, from optimizing the use of the constraint to potentially removing or mitigating its impact.

Optimizing the Constraint

The primary strategy is to optimize the use of the constraint resource. This can involve various tactics, such as maximizing resource utilization, where the constraint resource is used as efficiently as possible. This might include implementing shift work, overtime, or even outsourcing certain tasks to ensure the resource is utilized to its fullest potential.

Another approach is buffer management, which involves creating buffers of time, inventory, or other resources before the constraint to account for variations in demand or supply. This strategy can help smoothen the flow of work or materials to the constraint, reducing delays and inefficiencies.

Removing or Mitigating the Constraint

In some cases, it might be possible to remove the constraint altogether. This could involve improving the resource itself, such as upgrading machinery or providing additional training to employees. For example, if a production line is the constraint due to its slow speed, investing in new, faster machinery could remove this bottleneck.

Alternatively, redesigning the process to bypass the constraint might be an option. This could involve restructuring work procedures, reallocating resources, or even adopting new technologies to achieve the same outcome without relying on the constraint resource.

Case Study: Toyota’s Just-in-Time (JIT) Production

Toyota’s famous JIT production system is an excellent example of effective constraint resource management. In this system, production is based on actual demand, with inventory levels kept to a minimum. This approach minimizes the risk of excess inventory and ensures that resources are not wasted.

By keeping inventory levels low, Toyota effectively identifies and manages constraint resources. If a particular part or resource becomes scarce, it immediately becomes a constraint, triggering actions to either increase supply or find alternatives. This system ensures that resources are used efficiently and that any bottlenecks are quickly identified and addressed.

The Impact of Effective Constraint Resource Management

Managing constraint resources effectively can have a profound impact on an organization’s performance and competitiveness. By identifying and addressing constraints, organizations can significantly improve their operational efficiency, reduce costs, and increase productivity. This, in turn, can lead to improved customer satisfaction, enhanced market position, and increased profitability.

Enhanced Operational Efficiency

By optimizing the use of constraint resources, organizations can streamline their operations, reduce waste, and improve overall efficiency. This can lead to faster production times, reduced lead times, and improved quality, all of which can give an organization a competitive edge.

Cost Reduction and Profit Maximization

Effective constraint resource management can also lead to significant cost savings. By identifying and addressing bottlenecks, organizations can avoid costly delays, reduce waste, and improve resource utilization. This can free up resources that can be allocated to other areas of the business, leading to potential cost savings and increased profitability.

Improved Customer Satisfaction and Market Position

By managing constraint resources effectively, organizations can deliver products or services more efficiently and consistently. This can lead to improved customer satisfaction, as customers receive their products or services on time and to the expected quality standards. Additionally, by improving operational efficiency and reducing costs, organizations can potentially offer more competitive pricing, further enhancing their market position.

Future Implications and Innovations

As industries evolve and technologies advance, the strategies for managing constraint resources are also evolving. The increasing adoption of technologies like Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT) is expected to revolutionize constraint resource management.

Role of AI and ML in Constraint Resource Management

AI and ML can play a significant role in identifying constraint resources more accurately and efficiently. These technologies can analyze vast amounts of data, identify patterns, and predict potential bottlenecks. For example, ML algorithms can analyze historical data to identify trends and patterns that might indicate a potential constraint, allowing organizations to take proactive measures.

Furthermore, AI and ML can also be used to optimize the use of constraint resources. For instance, ML algorithms can optimize production schedules to ensure the most efficient use of resources, or AI systems can predict maintenance needs for machinery, ensuring they are serviced before they become a constraint.

IoT’s Impact on Constraint Resource Management

The IoT is another technology that can significantly impact constraint resource management. By connecting various devices and sensors, the IoT can provide real-time data on the status and performance of resources. This data can be used to identify constraint resources and manage them more effectively.

For example, sensors on machinery can provide real-time data on their performance, indicating if they are operating at capacity or if they are likely to fail soon. This information can be used to optimize maintenance schedules or even predict and prevent failures, ensuring that these resources do not become constraints.

Frequently Asked Questions (FAQ)

What is a constraint resource, and why is it important to manage it effectively?

+

A constraint resource, often referred to as a bottleneck, is any element in a system or process that limits the overall output or efficiency. Effective management of constraint resources is crucial as it can significantly impact operational efficiency, cost reduction, and market competitiveness. By identifying and addressing constraints, organizations can streamline their operations, reduce waste, and improve overall productivity.

What are some common methods used to identify constraint resources?

+

Common methods include the Theory of Constraints (TOC) developed by Eliyahu M. Goldratt, and the Critical Path Method (CPM) used in project management. TOC focuses on identifying and improving the most limiting factor in a system, while CPM identifies the longest sequence of dependent activities to complete a project, highlighting critical resources.

How can organizations optimize the use of constraint resources?

+

Organizations can optimize the use of constraint resources through various strategies such as maximizing resource utilization, implementing shift work or overtime, outsourcing tasks, and using buffer management techniques to smoothen the flow of work or materials to the constraint.

What is the role of AI and ML in constraint resource management, and how can IoT impact it?

+

AI and ML can enhance constraint resource management by analyzing vast data, identifying patterns, and predicting potential bottlenecks. They can optimize production schedules and predict maintenance needs, ensuring efficient resource use. IoT, on the other hand, provides real-time data on resource status and performance, helping to identify and manage constraint resources more effectively.

What are the potential benefits of effective constraint resource management for organizations?

+

Effective constraint resource management can lead to enhanced operational efficiency, reduced costs, and improved market position. It can streamline operations, reduce waste, and improve productivity, resulting in better customer satisfaction and increased profitability.